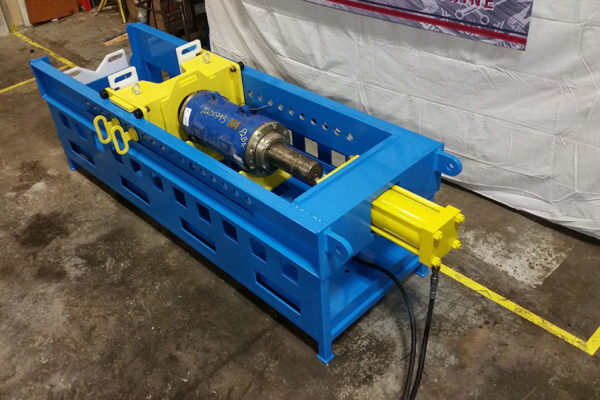

Our current horizontal press accommodates these brands and diameters but can we can adapted to any shape and size.

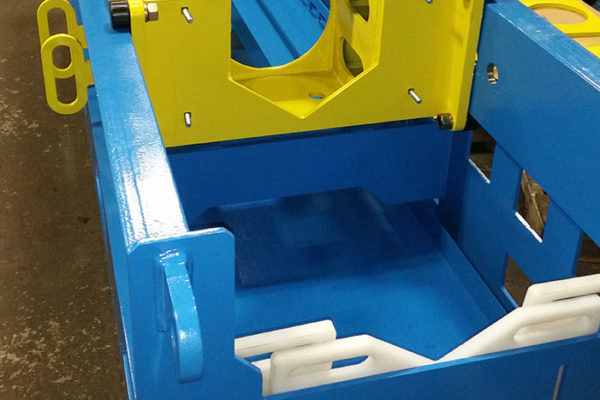

How the press works is you select a set of vee blocks to match the diameter of the barrel and insert them into the slot of the press frame.

You then set the pump barrel onto the vee blocks and either have the endcap bolts and bearing lock nuts removed before or after you set it in place.

The next step is to select the proper top clamp for that diameter of barrel.

Once the top clamp has been set in place and pinned into position you can use the power unit to remove the endcaps & bearing assemblies.

There is a bolster frame with UHMW supports for shafts to slide on during disassembly.

The hydraulic power unit can be selected to match power requirements for site specific voltages.